Is a Handheld Edger Right For You?

03.02.2017 | Todd Carroll

In 2006, new ski-tuning tools made a grand entrance into the ski racing world; handheld, machine operated tools! Starting at the professional ski racing level, the TRIone and Snowglide were the talk of the town. Technicians were heard discussing razor sharp and butter smooth edges, and doing so outside of the ski room, which was unusual given their typical workload. These new tools offered a result the technicians were accustomed to, but they required far less time to get there. Given the apparent advantage of these tools, it did not take long for coaches, parents, and athletes at the non-national team level to start paying attention.

Fast forward to today – there are no less than six tools of this type on the market, at varied price points, and each with a cadre of fans and opponents. While you might get a different opinion about which tool is best depending on whom you ask, the mere idea of using a handheld edging machine remains polarizing. With all of the options, including the traditional method of tuning solely by hand, it can seem overwhelming when trying to figure out which machines to consider.

6 options we will discuss here are….

Fogman World Cup Edge Grinder ($1295)

Montana Monty Edger ($2749)

ProTek Edge Bevel Grinder ($1495)

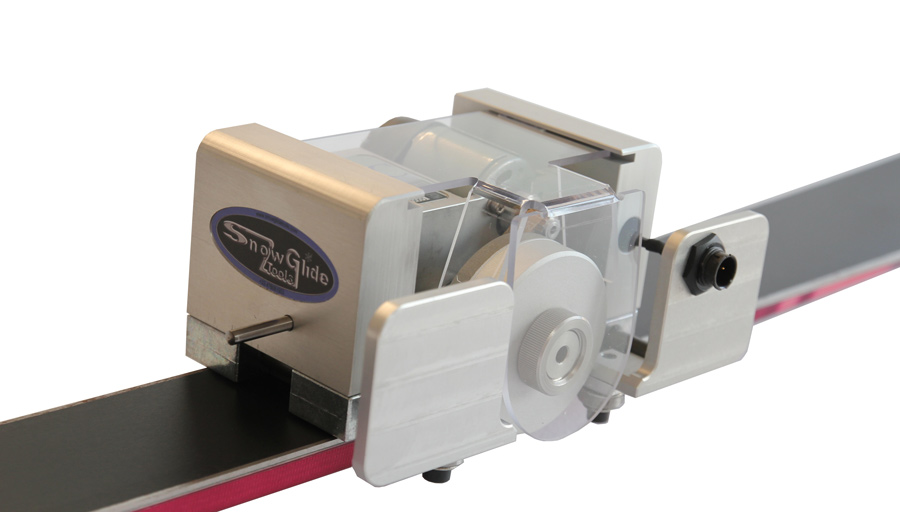

Snowglide AF-C and AF-L ($1700 and $2400)

TRIone Side Edge Sharpening Tool ($2499)

So, after a collective deep breath, we can dive into an analysis of the tools, talk about the pros and cons, and arm you with the information to make an informed decision about what is best for you.

As a starting point, it is important to keep in mind why we tune skis. While the application can vary, the goal is the same – to eliminate or minimize equipment as a variable in the success equation. Success is subjective; it could be qualifying for the NASTAR National championship or toughing out a day in Vermont when it rained the previous night and froze hard in the morning. Regardless of your definition or reason, the aim should be consistency in your tuning.

With consistency and reliability in mind, advocates (this writer included) will point out that each machine available shows distinct advantages over hand tuning by the average coach, parent, or athlete. While some naysayers might argue that they prefer the ‘feel’ of doing the work by hand, the plain reality is that tuning by hand offers too many moving parts for the non-professional technician to do so uniformly day in and day out. Even the steady hand of a seasoned shop pro quickly becomes dicey: stones and files wear, spring clamps loosen, and tools flex … the end result being inconsistency.

Moving beyond the advantage that machines provide with uniformity, the next issue becomes edge sharpness and quality. Score one for any cynic who says that you can get a ski just as sharp by hand as you can with a machine. While sharpness is not entirely binary (sharp or not), it is possible to get a ski sharp by hand.

However, all that hand tuning to get edges sharp and smooth takes time, which is another gold star for handheld machines. No technician is capable of producing such a defined, precise, and sharp edge by hand as quickly as can be created with a machine. For sure technicians at the highest level will polish the machine finish to a finely honed point; but for junior athletes and weekend warriors, the machine finish can be ceramic stoned (two passes) and then ‘broken’ lightly with a leather stropping, paper towel, or a chamois. Just like hand tuning, personal preference dictates how much gummi stone work is done to detune the tips and tails.

So, with a pretty clear level of superiority for machine tuning, the questions and comments start flying. What about the actual tools themselves? Surely there has to be one that outshines all others. Look at that price! I can get a lot of bevel guides, files, stones, and clamps for that amount of money. C’mon, the factory finish on my skis is great! I can just maintain things by hand, right?

To start, the factory finish on most race skis has improved dramatically in the last 10 years, but still leaves a fair amount to be desired. The idea of maintaining a factory finish is noble, but the issues that plague hand tuning are not mitigated by the fact that your skis came with a proper bevel angle or are smooth and sharp. In fact, it speaks volumes about the advantages of machine-based tuning that race skis are delivered with a machine-finished edge.

When it comes to the tools themselves, you will see subtle differences between each. These tools are similar to wax systems – with each system there is a new set of parameters to learn. Generally speaking, you can pick a machine, run with it, and you will quickly learn the ins and outs of proper, efficient operation. That said, there is one aspect that is absolutely critical and worth mentioning – user-friendliness.

Within the realm of user-friendliness, there are two common themes amongst the majority of machines in this article: the first is that five of them require some degree of cut depth adjustment by the user, and a novice user could remove way more material than necessary without proper instruction. The second is that four of them (Discman, Fogman, Monty, and TRIone) operate with the ski base facing the operator and machine motor positioned above the edge, which can lead to tipping and alteration of edge angle. Both of these potential issues can be lessened with training and experience running the machines. But only the Snowglide machines address both without requiring anything extra from the operator.

Moving onto the question of price, that is certainly a tough one. Ski racing is expensive; there is no argument about that. All of the pieces add up to a very pricey puzzle, and the addition of $800 to $2800 more to the mix can be a deal breaker for many. One thing to keep in mind when you are considering the price is the value you get from the machine. Do you want to make sure that your athletes are ready for any conditions they may encounter during a costly training session? How about spending some more time with your family or friends away from the tuning bench? And do not forget the cost of race entries and what ill-prepared skis mean there.

Lastly, an oft-ignored area to mention is safety. All edge machines generate fine, metal particulate. Inhaling this particulate is a bad idea, so be sure to use a respirator or, in a pinch, a painting mask when operating these machines. You will undoubtedly hear the hand tuning crowd railing against machines for this very reason, however, they often do so while running a wax iron too hot and without any protection against the burning hydrocarbons that are being inhaled. Use common sense; follow the warnings provided with each machine, and you will be fine.

At the end of the day, between the options available and the job they do, there is little room for arguing against handheld edging machines. You would likely choose a machine cut and welded frame for a metal outbuilding at your house versus having your neighbor do the work with a welder and chop saw. So why would ski tuning be any different? And, when you really want to eliminate equipment as a variable in your success equation, it is definitely time to take a hard look at modernizing your process.